The Boeing Company, founded in 1916, hit a low point in 1934 when it was forced out of the airline business and was forced to concentrate on its original airplane-manufacturing business. The company's fortunes revived in the buildup to World War II. Thousands of workers swarmed over Boeing's plant on Seattle's Duwamish River, making the bombers and fighters that helped win the war. Employment topped 50,000 by 1944. After the war Boeing entered the newly lucrative commercial-airliner market, and the Cold War revived its military contracts. In the 1950s and 1960s it diversified into an aerospace company and built missiles and rockets. The demise of the SuperSonic Transport (SST) program in 1971 resulted in the infamous Boeing Bust, a statewide economic downturn caused by the loss of 86,000 jobs. Boeing recovered over the ensuing decades, despite increasing competition from Europe's Airbus. Meanwhile, hundreds of other aerospace companies sprang up in Washington to supply parts. Boeing's headquarters moved from Seattle to Chicago in 2001, yet Boeing's assembly plants in Renton and Everett continued to hum. As of 2015, the company employed more than 80,000 Washington workers and the state's aerospace suppliers employed many thousands more.

The airplane company founded by William E. Boeing (1881-1956) had grown into a Seattle manufacturing powerhouse and nationwide air-transportation system by the early 1930s. While the rest of the country was mired in the worst year of the Great Depression in 1933, Boeing employment reached a new high of 2,264. Yet the Boeing Company hit major turbulence in 1934, when the U.S. Congress accused the company of monopolistic practices and forced it to dissolve United Aircraft and Transport, its passenger airline system, which was reincorporated as an independent company under a new name, United Airlines. A bitter Bill Boeing sold most of his shares, retired, and never again played a significant role in the company he founded.

The next year, 1935, the company's payroll dwindled to 839. However, war rumblings from Europe soon revived Boeing's fortunes, along with those of the broader Puget Sound economy. Boeing received orders from the Army Air Corps for dozens of bombers in 1936 and the company's payroll soared, reaching 2,956 workers in 1938 and nearly 6,000 by the end of 1939. With success came labor troubles. The Aero Mechanics' Union threatened to strike in 1940 and Boeing, in retaliation, threatened to move to Portland or San Francisco. This would have spelled economic trouble for all of Washington, because the company was now firmly ingrained in the state's economy. In the end, Boeing accepted arbitration and the labor strife slowly eased, in part because the threat of a new war in Europe brought both sides together. Boeing would remain in Seattle.

The attack on Pearl Harbor in 1941 sparked an unprecedented explosion in Washington's aviation industry. The company's Duwamish River complex in South Seattle was covered with camouflage netting so that hostile eyes could not see what was happening below: tens of thousands of workers feverishly building thousands of airplanes, including two of the most famous American aircraft of the war, the B-17 Flying Fortress and the B-29 Superfortress. Boeing was no longer merely a regional economic powerhouse; it "instantaneously became a major national business enterprise" (Ficken and LeWarne, 131). By 1944, nearly 50,000 people worked for Boeing. The company had expanded along the Duwamish River and into the suburb of Renton southeast of Seattle. Boeing sales for 1944 exceeded $600 million, a number unthinkable before the war. This was 10 times the total sales for all of Seattle's industry in 1939. Seattle's population skyrocketed and many of those newcomers were working long hours and making good money at Boeing.

The company's presence was now felt all across the state. For instance, aluminum, produced with cheap hydroelectric power in Spokane, Longview, and other cities, almost immediately became the state's second-biggest wartime industry. Much of that aluminum was bound for Boeing, where it was fashioned into wings and fuselages. Personal income was tripling across Washington, partly because of "the narcotic effects of war contracts," as one Seattle newspaper put it (Ficken and LeWarne, 130). Meanwhile, the state's community and technical colleges had begun offering aviation training programs as early as 1941, when the school in Pierce County that would evolve into Clover Park Technical College started training aircraft mechanics.

For Washington's economy, "the postwar era began not ... aboard the battleship Missouri, but in the board room of the Boeing Company" (Ficken and LeWarne, 144). With peace in 1945, it appeared that the state's aviation industry would crash again. The government immediately canceled most of its B-29 contracts and Boeing's board slashed the workforce to 11,000. This was perilously close to the critical mass "below which the company could not survive" (Bauer, 108). Boeing pulled out of this dive by converting one of its cargo planes to a commercial airliner, the Stratocruiser, and pursuing the growing commercial-aviation industry.

Then, as the 1950s began, the Cold War and the Korean conflict created a renewed demand for military aircraft. Boeing developed the B-47 and the groundbreaking B-52 Stratofortress. Over the next decades, Boeing would build 744 of the massive B-52 jet bombers, more than 60 of which were still in use in 2015, 60 years after the plane first entered service. Then came the KC-135, an Air Force tanker built in Renton, and a series of commercial jetliners, including the hugely popular Boeing 707 and Boeing 727. Boeing had not merely survived the postwar era, it was thriving on an unprecedented scale. In 1957, employment topped 100,000 for the first time. Yet for the state's economy, "Boeing's own success proved a mixed blessing" (Ficken and LeWarne, 145). The workforce and the economy continued to careen up and down in sometimes sickening lurches, depending on the whims of the commercial-airplane market and the stiff competition for military contracts.

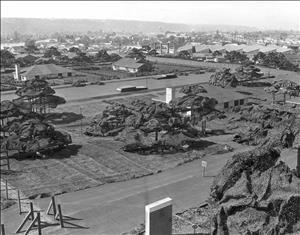

Boeing's solution was to diversify. As the 1960s began, space became a key part of President John F. Kennedy's New Frontier. Boeing had already entered the missile business in the 1950s with its BOMARC supersonic antiaircraft rockets. Then in 1961 it won a contract to build Saturn rocket boosters. In 1963 the company acquired 320 acres of farmland in Kent and built the Kent Space Center, which would become the sprawling headquarters for Boeing's many space-related projects, including the Lunar Roving Vehicle that eight years later would ramble over the surface of the moon. Washington's aviation industry had evolved into an aerospace industry.

By 1966 Boeing was taking a hard look at its primary market, the airliner. Deciding that jumbo jets were the future, the company acquired Paine Field, an old wartime military base in Everett, and built what remains in 2015 the largest building by volume in the world. It was the assembly plant for the company's new jumbo jet, the Boeing 747, and the workforce soon exceeded 20,000 at Everett alone. The first 747 rolled out of the giant building in 1969 (by 2014, Boeing had built 1,500 747s and counting).

The 747 also marked a turning point in the way the company built its planes, with enormous implications for Washington's economy. Only the wings and the forward body sections, including the flight deck, were actually manufactured in the Boeing plant. More than 65 percent of the 747 was subcontracted to other companies. Tellingly, the Everett plant was called an assembly plant, not a factory. To a significant degree, the 747 was being built in widely scattered workshops and factories all over the state and all over the world and then assembled in Everett. This trend would accelerate over the next few decades. A running joke in Seattle went like this: "A Boeing airplane is forty-five thousand pieces flying in close formation" (Newhouse, 168).

Airplanes had become so complex that it made sense to farm out some parts to specialists. Some of these suppliers were clustered in the Puget Sound area and were founded by former Boeing employees who had struck out on their own. Others were scattered around the state and utilized the aerospace knowledge of retired Air Force personnel from Washington's many air bases. And many of the suppliers were overseas. Still, assembling and integrating all of these pieces in Everett and Renton remained a massive job. As the 747 project got rolling in 1968, employment at Boeing peaked at nearly 142,400, and many thousands more were working for Boeing's suppliers.

Then came the biggest Boeing downturn of all, the one for which the term Boeing Bust was coined. As the 1970s dawned, the airliner market was saturated and the country was slipping into recession. Boeing laid off more than 25,000 workers in 1969 and another 41,000 in 1970. Then in 1971 came devastating news. The U.S. Senate cut funding for Boeing's sleek new Supersonic Transport, known as the SST, and the company cut nearly 20,000 more jobs. The workforce hit a low of 56,300. This Boeing Bust had put 86,000 workers on the street in three years.

"Seattle and the Puget Sound region -- where most of the people were employed -- became a disaster area; and statewide, Washington unemployment hit 14 percent, highest in the nation. Someone placed a huge sign adjacent to Interstate 5, with the grim admonition, 'Will the last person leaving Seattle turn out the lights'" (Bauer, 216).

The company -- and the state's aerospace industry -- engineered a remarkable comeback over the next decade. Boeing landed several lucrative military contracts, including the Airborne Early Warning and Control System (a radar plane known as AWACS), built in Renton, and air-launched cruise missiles, made at the Kent Space Center. The company also made a crucial strategic pivot: It decided to target "overseas commercial sales as its top priority" (Bauer, 216). By 1972, the company was selling to airline customers in Romania, Egypt, Iraq, Sudan, and, of special significance for the future, China. Japan Air Lines had, for decades, been one of Boeing's largest customers, and it operated a pilot-training center at the former Larson Air Force Base in Moses Lake, Grant County, for more than 40 years. As of 1978 more than half of Boeing's commercial airliner orders were foreign. Boeing had by then become the country's largest single exporter and earner of foreign capital and it would continue to remain near the top.

However, the trauma of the 1971 Boeing Bust had hurt nearly everybody in the state, not just Boeing workers. It was seared into the collective psyche. Washington's policy makers and business leaders put a great deal of effort into diversifying the state's economy. This effort eventually reached fruition in the 1990s with the rise of Microsoft, Amazon, and the high-tech industry. That helped to alleviate the "mixed" portion of the "mixed blessing" that was Boeing. Meanwhile the "blessing" part was still obvious with Boeing's employment rebounding back to more than 100,000 by 1980.

The company still towered over its aerospace competitors, but by the late 1980s that began to change. An upstart European company called Airbus was beginning to cut into the market, partly because it was able to build airplanes more cheaply than Boeing. The reasons for this became a subject of fierce international debate in the mid-1990s. In some American circles -- and especially in Boeing's home state -- Airbus was considered to have an unfair advantage over Boeing because a consortium of European governments subsidized it. In fact, Airbus had been conceived because the governments of Britain, France, Spain, and Germany were worried that they would lose their national aircraft corporations altogether to the Americans, i.e. Boeing. But how could Boeing be expected to compete with a company whose losses could be covered by government money? In Seattle people felt it smacked of "socialism," or at least an unfair playing field, while on the other hand Europeans were appalled at "Boeing's habit of laying off thousands of highly trained mechanics in slack periods" (Newhouse, 10). In fact, in 1992 Boeing announced another layoff of 28,000 workers.

The debate came to a head when President Bill Clinton (b. 1946) visited Seattle that year and said that many of the layoffs wouldn't have happened without the $26 billion that European governments had plowed into Airbus: "The Europeans are going to have to quit subsidizing Airbus ... I am not going to roll over and play dead" (Newhouse, 47). Seattle's economy, noted Clinton, was the most export-dependent in the U.S. and a model for a nation increasingly concerned about growing overseas-trade gaps. An international agreement did, in fact, partially limit Airbus subsidies, but it didn't appear to help Boeing. In 1993, Moody's downgraded Boeing's debt rating for the first time in company history. The subsidies debate would drag on toward stalemate.

Once again, the state's aerospace industry lurched up and down. In 1997, Boeing merged with one of its chief competitors in the defense field, McDonnell Douglas, as part of an attempt to further diversify and shield the company from the vagaries of the passenger-plane market. This didn't entirely succeed. A sharp downturn in air-passenger traffic occurred in the year following the September 11, 2001, terrorist attacks, which also resulted in fewer airplane orders. In the years following the attacks, Boeing laid off nearly 30,000 people and the company's Washington workforce dropped to around 54,000. This happened while the state was still reeling from a shocking announcement in May 2001: Boeing was moving its corporate headquarters to Chicago. Could this spell the beginning of the end for aerospace in Washington? The Boeing president fueled the paranoia by saying, "We don't want to be off in a corner of America" (Newhouse, 197).

The executives packed up and left, creating an upper tier far removed from the nuts and bolts of the business. Yet the headquarters of the Boeing Commercial Airplanes unit of the company remained in Seattle, and the airplanes were still being churned out in Everett and Renton. No matter where the corporate suites were, the airplanes still had to be assembled in a state with a trained workforce that knew how to build them.

In 2004 the workforce was once again at low ebb -- about a hundred thousand Boeing jobs had vanished in the Puget Sound area since the 9/11 attacks, for total employment of just above 52,000 in Washington -- and spirits were even lower. Aerospace seemed to be in a slow decline and high tech seemed to be soaring. "By then, Boeing was widely seen as peripheral, an ex-spouse who is still hanging around the neighborhood" (Newhouse, 199). Then, once again, Boeing bounced back. Another new and innovative airplane, the midsize Boeing 787 Dreamliner, was conceived in 2003 and began production in Everett and -- ominously for Washington -- at a new plant in South Carolina. The 787's launch was delayed until 2011, but by then it was already what the company website called the "fastest selling wide-body airplane in history" ("Historical Snapshot"). Boeing was once again outselling Airbus.

The 787 reflected the company's new way of making airplanes. More of its manufacturing than ever was outsourced to suppliers. Many of these were huge overseas companies, such as Japan's Mitsubishi, Fuji, and Kawasaki. Hundreds of others were spread all over the Puget Sound region and the rest of Washington. The 787 was especially innovative in its use of composites -- carbon-fiber-reinforced plastic -- to replace aluminum. About half of the plane's primary structure, including the fuselage and wing, were made of composite materials. Partly because of this, a composites industry -- a labor-intensive manufacturing process -- sprang up in Washington.

Several developments in 2011 signaled a new aerospace boom in Washington. In February, after a long and controversial competition with Airbus, Boeing won a U.S. Air Force contract to build a new long-range aerial-refueling tanker, the KC-46, based on the Boeing 767. An estimated 179 of these began production in Everett. In addition, Boeing announced a new version of the 737, its bestselling model, to be called the 737 MAX. All the while, the current 737 versions, including the 737-900, were still hot sellers. In 2012 the 737 in all versions became the first commercial jet to surpass the 10,000 mark in sales. The Renton plant began producing 737s at the remarkable rate of 42 per month. Total Boeing employment was at around 165,000, of which about 77,000 were in Washington. The number of aircraft ordered by customers went above 800 in 2011, compared with fewer than 300 just two years earlier, and then well above 1,000 in 2012. Most significantly, Boeing's Washington employment numbers were climbing, to a peak of 87,000 in 2012. Washington employment would fluctuate slightly over the next few years but through mid-2015 had not dipped below 80,000.

Meanwhile Boeing had spawned a huge network of smaller companies that were suppliers to Boeing and the larger aerospace industry. Some of these were composites companies, such as Janicki Industries Inc. in Sedro-Woolley, Skagit County, and Hexcel Corporation in Kent. Some were electronics and engineering companies, such as Absolute Aviation Services in Spokane. Some had started as Boeing-owned companies and had been sold along the way, such as Triumph Composite Systems in Spokane. The nonprofit trade organization Pacific Northwest Aerospace Alliance represented more than 500 companies.

Yet by 2013 anxiety was once again building throughout the state about the future of this crucial part of the state's economy. Boeing hinted that the new 777X project might be moved to South Carolina, Utah, or Texas. In November 2013 the Washington State Legislature held a weeklong special session devoted exclusively to coming up with a package of tax incentives, infrastructure improvements, and worker-training programs aimed at keeping the project in the state. Legislators subsequently passed $9 million in tax breaks for Boeing and $8 million for aerospace training. The package was contingent on the 777X project remaining in Washington.

As a result, Boeing remained a robust linchpin of the state's economy, as it had been for most of its century of existence. As of July 2015, Boeing employed 80,145 people in Washington. The company had secured 1,535 airplane orders in 2014 and hundreds more through the middle of 2105. Production of the 777X was set to begin in 2017 -- in Everett. However, if Washington's aerospace history taught one clear lesson, it was this: At some point, the ride will once again get bumpy.