The Georgetown Steam Plant was built by the Boston-based Stone & Webster utilities conglomerate, which held a dominant position in electricity generation and public transportation in the Seattle area during the early twentieth century. By the time the plant began operating in 1907, much of the company's electricity came from hydropower, with steam generation used to increase peak-load capacity and as back-up against service interruptions. In later years the Georgetown plant remained largely idle, although it was maintained in operating condition for decades. In 1951 Seattle City Light purchased Stone & Webster's Seattle properties, including the Georgetown facility. Its boilers and generators were fired up only on rare occasions in the years since. The plant's overall contributions to electricity production were minor but the innovative methods and materials used to build it, the intact early-twentieth-century steam-generating equipment it houses, and the involvement of pioneering efficiency expert Frank Gilbreth in its design and construction give the Georgetown Steam Plant significant historical importance. The plant, located near Boeing Field in South Seattle, has been designated a National Historical Mechanical Engineering Landmark and a National Historic Landmark.

Electrifying Events

Electricity went from novelty to necessity with remarkable speed. Just eight years after a Belgian, Zénobe Théophile Gramme (1826-1901), demonstrated the first commercially feasible direct-current (DC) dynamo, American inventor Thomas Alva Edison (1847-1931) unveiled an incandescent bulb in 1879 that used DC current to produce artificial light, something so useful and desirable that it ensured public demand for the still-mysterious force that made it possible. Three years later, the world's first hydroelectric plant produced direct current from a dynamo on the Fox River in Wisconsin.

But DC quickly lost potency with distance and was practically useless more than about a mile from its source. In 1887 Nikola Tesla (1856-1943) developed a complete system of generators, transformers, and motors that produced and used alternating current (AC), which could travel much farther than direct current. Industrialist George Westinghouse (1846-1914) backed Tesla and bought many of his patents, then waged a long battle against Edison, who had bet on direct current. In 1895 the Westinghouse Electric & Manufacturing Company installed three Tesla-designed hydroelectric generators at Niagara Falls that sent alternating current by wire 20 miles to Buffalo, something DC could not do. Edison fought on for years but alternating current became America's standard for most purposes, and that is what the Georgetown Steam Plant was built to produce.

Seattle Electric Lighting

In 1886 the Edison-backed Seattle Electric Lighting Company installed in a shed on Jackson Street a reciprocating steam engine that powered a dynamo to produce direct current for a few nearby customers and a handful of street lights. This was reputed to be "the first central station system for incandescent electric lighting west of the Rocky Mountains" ("Puget Sound Power ...").

By March 1889 Frank Osgood (1852-1934), owner of a horse-drawn streetcar service in Seattle, had an electric streetcar system, the first on the West Coast, up and running in the city, using direct current from a steam plant on Pike Street. Osgood's streetcars rattled on uninterrupted during the Great Seattle Fire that swept the city three months later. This demonstration of reliability stimulated public demand for electricity and that demand encouraged a stampede of investors hoping to capitalize.

Because direct current had to be used near its source and because young Seattle was full of optimistic entrepreneurs, a profusion of small, steam-powered electrical plants cropped up around the city, each serving only nearby customers and streetcar lines. It did not take long, however, for ownership of the city's electric and streetcar systems to be consolidated.

Consolidation

Charles Stone (1867-?) and Edwin Webster (1867-1950) started their careers together as consulting engineers and ended up running one of the nation's largest electrical and urban-transportation conglomerates. By the early 1900s they operated power plants in six states and controlled electric lighting systems and railways in a number of cities.

Their company, Stone & Webster, turned its attention to Seattle in 1898, working first with William J. Grambs (1862-1943), who became Stone & Webster's local agent in 1899. On January 19, 1900, Grambs incorporated the Seattle Electric Company, which soon had gathered under Stone & Webster's management nearly all of the steam-powered generating plants in the city.

By 1902 Stone & Webster controlled all the streetcar companies in Seattle and almost all the city's electricity production, and had completed an electric interurban rail line linking Tacoma and Seattle. In 1912, the Seattle Electric Company and Stone & Webster's streetcar and interurban holdings were combined to form the Puget Sound Traction, Light & Power Company. In 1918, Seattle purchased the company's streetcar lines in the city and the following year the word "Traction" was removed from the company name.

Water and Steam

Hydroelectric generation emerged early as the clear choice in the water-rich Northwest. In 1904 Stone & Webster completed the Electron Power Plant in the Cascade foothills southeast of Tacoma, where a 10-mile-long wooden flume carried water from the Puyallup River to an artificial lake. This fed into a penstock, which directed the flow over the blades of a waterwheel connected by a shaft to an AC generator. The electricity was sent along transmission lines to Seattle, nearly 50 miles distant, and to Tacoma, 32 miles away.

In 1908 another Stone & Webster company bought the hydropower plant at Snoqualmie Falls, which when built in 1899 was the first in the region. In 1910 the company put in a second powerhouse just downstream from the falls, and in 1911 Stone & Webster opened a hydroelectric project that tapped the White River and created Lake Tapps in Pierce County as a reservoir from which to feed the generators.

Even with all this hydropower, steam generation met a critical need. The more indispensable electricity became, the more necessary it was to ensure a reliable and adequate supply. The complexity of Stone & Webster's electrical grid offered multiple avenues to failure. Without adequate backup, interruptions in supply and the occasional inability to meet peak demands could not be avoided.

Also, by 1906 Stone & Webster's near-total monopoly over Seattle's electrical supply had come to an end. In 1902 the city's voters overwhelmingly approved a $590,000 bond measure to finance a municipal hydropower plant on the Cedar River. In 1905 the city Lighting Department (later Seattle City Light) took over Seattle's street-lighting circuits from the Seattle Electric Company and began providing power to city residents. Facing competition, Stone & Webster sought to ensure reliability by building generating capacity well beyond normal demands. A decade later, early Seattle historian Clarence Bagley summed up the important role of the company's steam plants in this effort:

"In order to provide for any contingency, four powerful steam plants are maintained, one each at Tacoma and Everett and two in Seattle. Despite the fact that water power is so dependable that not 1 percent of the current is generated annually by the steam plants, these are kept in readiness for instant action in an emergency. It is this state of constant preparedness that makes the company's service so perfect" (History of Seattle, 442)

Stone & Webster's service was never "perfect," but it did try. For its second Seattle steam plant (the first had been built on Post Avenue in Pioneer Square in 1902), the Seattle Electric Company in 1906 purchased 18 acres of land along the east bank of the Duwamish River in Georgetown, then still an independent city (it was annexed into Seattle in 1910). The Duwamish provided a virtually limitless source of water to convert to steam and to cool the condensers that closed the loop and returned the water, considerably warmer, to the river. Land there was inexpensive, and the transmission line from the Electron hydropower plant passed nearby. Stone & Webster's car barns and maintenance shops were already located in Georgetown, and the tracks of its Seattle-Tacoma interurban passed in close proximity.

The Remarkable Gilbreths

The Seattle Times reported on March 30, 1906, that workers had broken ground that day for the construction of the Georgetown Steam Plant, although a decision was yet to be made whether it should be built of steel and brick or reinforced concrete. The article also noted that Frank Bunker Gilbreth Sr. (1868-1924), a well-known expert in both methods, had been hired to design and build the facility.

Gilbreth was trained as a bricklayer in his youth and soon was seeking ways to make that trade less arduous and more productive. Watching his fellow bricklayers, he noticed that they were almost all doing the job a little differently, and with more stooping, walking, and reaching than seemed necessary. He developed a systematic approach that reduced the number of motions needed to lay a single brick from an average of 18 to five and increased the productivity per worker from an average of 125 bricks per hour to 350. Gilbreth had found his true calling, and he went on to build a very successful career in what he called scientific management.

In 1904 Gilbreth married Lillian Moller (1878-1972), who would later earn a doctorate in psychology. The couple became perhaps the world's first professional efficiency experts, studying films of workers to ferret out wasted effort and streamline production across a range of occupations. They identified 18 basic units of activity that in combination could complete any specific task, which became known as "therbligs," from "Gilbreth" spelled backward ("Pioneers in Improvement ..."). The couple somehow also found time to have 12 children, two of whom later wrote Cheaper by the Dozen, a best-selling book about the family that was twice made into a movie, in 1950 and again in 2003.

Gilbreth also created a systematic approach to building with reinforced concrete, a material first used for substantial construction in the 1880s. He developed step-by-step methods for engineers and workers, detailing how to proceed from the first shovel in the dirt to the finished product. By 1906 he was recognized as a leading expert in building power stations, dams, and other large reinforced-concrete structures.

Shortly after Gilbreth arrived in Seattle he learned that getting the necessary structural steel for a brick building would cause considerable delay. Then, on April 18, 1906, San Francisco was hit by a massive earthquake. The failure there of several steel-framed brick buildings gave additional support to a decision to build the Georgetown plant using reinforced concrete, a material far more resistant to seismic forces and the vibration of heavy machinery.

A Gilbreth System in Practice

Gilbreth had workers excavating the site before the ink had dried on the contract. Two pile-driving crews shadowed the excavators, each assigned to pound in half of the 1,712 pilings that would anchor the structure to the land. Gilbreth later wrote that "a series of athletic contests was begun" as the two crews competed to finish first (Concrete System, 131). Encouraging such presumably friendly competition between crews was a standard Gilbreth practice on this and other projects.

Everything at Georgetown was done on a just-in-time basis. While the pile-driving was underway, the working drawings for the foundation were being finalized, and as the foundation was being poured, the drawings for the superstructure were prepared. To ensure timely arrival of the concrete's steel reinforcing rods, Gilbreth dispatched a freight expert to the mill in Pittsburgh to supervise the loading of the material onto flatcars and to accompany the shipment to Seattle. With the shipment underway, exterior staging was erected to the full designed height of the building on all four sides. From this scaffolding the forms for the building's walls could be built in stages and concrete poured as each stage was completed. Four double elevators were used to hoist lumber, steel reinforcing rods, and mixed concrete from ground level to where it was needed.

While crews worked on the exterior walls from the staging, others toiled in the cavernous interior, assembling steel-reinforced forms for the concrete columns and girders that would tie the structure together and bear the weight of the floors, equipment, and roof. Two concrete-lined tunnels were run to the Duwamish River, one bringing water to be converted to steam and for cooling and the other returning the water to the river after it was condensed back into liquid form. (In about 1917 an ongoing project to channelize the Duwamish moved the river some distance from the plant, requiring the addition of a pumping station for intake water and extension of the discharge tunnel.)

By all accounts, the construction was carried to completion with barely a hitch. In his book Concrete System, published in 1908, Gilbreth could write with justifiable pride:

"We have recently designed, detailed, and constructed and guaranteed for a well-known firm of Boston engineers, a power station built entirely of reinforced concrete in Seattle, Washington. Even the coal bunkers, ash hoppers, and girders for the 30- and 50-ton travelling cranes, and the six girders of the roof over the engine house, 64' 2" long, are of concrete. As this power station was finished within the required time and below our estimated cost, and is a success from every standpoint, it is a good job for our men to study in order to copy those points that will make for success on future work" (Concrete System, 131).

The Boiler House

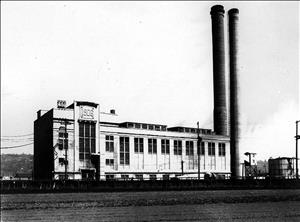

The architectural design of the Georgetown Steam Plant was Neo-Classical Revival, a rather overblown, monumental style that became popular in the 1880s for government and industrial buildings. Although detailed specifications are beyond the scope of this essay, a general description is helpful.

The entire structure is oriented in a roughly northwest to southeast direction and is adjacent to what is now the northwest corner of King County International Airport (Boeing Field), whose main runway opened in 1941. The steam plant's foundation slab measures 80 feet by 218 feet, and the building it supports comprises two main sections, the Boiler House and the Engine House, separated by a six-inch-thick interior wall of reinforced concrete. The structure's maximum height, measured at the roof of the clerestory atop the Engine House, is approximately 80 feet.

The Boiler House is the larger of the two sections at 153 feet long and 76 feet wide and is divided into four levels. The exterior façade on the west has nine architectural bays separated by concrete pilasters, each bay having a set of two sash windows at the level of the third floor. Above the windows are recessed shutters used for ventilation. The east façade is also divided into nine bays, but windowless. A 268-foot Weber concrete chimney served the boilers until it and another tall stack were removed as flight hazards and replaced with induced-draft fans connected to low roof vents.

Oil was the fuel used for the first nine years of plant operations, but much of the original equipment in the Boiler House was designed to handle coal. A sloped conveyor belt on the exterior of the building's narrow south end carried coal to the fourth floor; from there the force of gravity alone did almost all the work. A continuous horizontal conveyor dropped coal from the fourth floor into eight funnel-shaped bunkers on the third, from which it was fed into boilers arrayed in two rows of eight on either side of the second floor. The residue of the burnt coal dropped into hoppers on the first floor and was deposited for disposal into two ash cars that ran on rails along the length of the Boiler House.

When the use of coal ended permanently in the 1940s, the exterior conveyer was removed and the high portal on the south wall of the Boiler House was sealed and replaced by a rectangular cast-concrete pediment, to which in 1985 a detail reading "No. 1" was added. At least one source says that the "No. 1" signified that the Georgetown plant was the first of five that were planned, the other four never being built. This explanation seems unlikely, as Georgetown was not the first -- it was preceded by the company's steam plant on Post Street, built in 1902. Also, by the time the Georgetown plant's coal portal was sealed in the 1940s, and even more emphatically by 1985, hydropower's complete dominance made it unlikely that any new steam-generation plants would be built in the area. If the prominent "No. 1" has some other significance, it is not apparent from the record.

The Engine House

Set perpendicular to the Boiler House at its north end is the smaller Engine House, where the steam produced by the boilers was used to generate electricity, then condensed back into water and returned to the Duwamish.

The west façade of the Engine House is divided into three bays, the center one having two rows of three tall windows each that extend from above the main entry doors and are topped at the roofline by a triangular cast-concrete pediment bearing the date "1906." The bays to its left and right each have a pair of tall sash windows under two smaller, fixed windows. The reinforced-concrete portion of the north wall is divided into five architectural bays, but otherwise featureless. Behind this wall is much of the plant's electrical equipment -- the switchboard, wire room, circuit breakers, and exciters (used to create an initial magnetic field in the generators).

In 1918 a 36-foot extension was added on the eastern end of the Engine House to make room for a 10,000-kw generator and related equipment. Its northern face is blank save one small window and an entry door. Lighter masonry sheathed in corrugated metal was used here, at least in part to provide a pressure-relief valve in the event of an explosion inside the building. This was not an excess of caution -- in April 1908, when the plant was practically new, a steam pipe in the Boiler House burst with a blast heard all over Georgetown. Two men were seriously hurt and one, Chief Engineer George Tucker, died of scalding injuries 10 days later.

The Age of the Turbine

Before the advent of hydropower, reciprocating steam engines were the only practical way to generate electricity in commercial quantities. Heated water was converted to steam in a pressurized boiler, then piped to a reciprocating engine where it was used to push pistons up and down. This up-and-down motion had to be converted to rotary motion through a flywheel, which was connected by a shaft to a generator. Reciprocating steam engines were reliable, but massive, heavy, and inefficient.

The first practical steam turbine engine was developed in the 1880s in England. In 1896 Charles Gordon Curtis (1860-1953) patented a new design that was one-eighth the weight and one-tenth the size of any yet developed. It would revolutionize the steam-generation industry, only to be supplanted by something even better just few years later.

Although steam turbines are complicated machines, they operate on a simple principle that is much more similar to hydropower generation, which also relies on turbines, than to the reciprocal steam engines they replaced. They extract thermal energy directly from steam by directing it at high pressure through sets of blades or "buckets," roughly analogous to those used by turbines in hydroelectric plants (where water, rather than steam, is the motive force). No more pistons going up and down, no more flywheels -- just steam spinning turbine blades to produce electricity, and a power-to-weight ratio that rendered all predecessors instantly obsolete. (By 2015 nearly 80 percent of the world's electricity was generated by steam turbines. The Northwest is an exception due to its wealth of hydropower.)

General Electric bought Curtis's patents in 1901 and retained him as a consultant to continue working on the design. In 1903 he collaborated with a GE engineer, William LeRoy Emmet (1859-1941), to develop a steam turbine that stood on end and was only 25 feet tall, yet generated up to 5,000 kilowatts of electricity, an output that was soon increased. This design instantly became the gold standard for steam generation.

Georgetown Generation

The Georgetown Steam Plant's first Curtis vertical turbine, producing 3,000 kilowatts of electricity, was tested on August 3, 1907. The turbine worked fine, but the attached generator almost immediately burned out and would do so three more times in quick succession. On December 17, 1907, a second, 8,000-kilowatt vertical turbine was added, but its generator also failed the next month. After intervention by experts from Stone & Webster's home office the problems were resolved, and both vertical steam turbines were fully operational by March 1908.

Turbine and generator technology continued to advance rapidly. In 1911 the smaller generator at Georgetown was reconfigured to increase its output to 5,000 kilowatts, but Curtis and GE had something better in development. The 36-foot extension added to the Engine House in 1918 was built to house one of the next generation of steam turbines, a 10,000-kilowatt Curtis. Technically far ahead of the vertical turbines, this one lay horizontally on a raised platform adjacent to the two vertical units. Although the impetus for its addition was increased electrical demand arising from America's entry into World War I, the new machine was not ready for use until seven months after the war ended, and by then it was barely needed at all.

Its Place in History

The Georgetown Steam Plant was in large part an expensive exercise in preparedness, built only to add incrementally to the Seattle Electric Company's capacity during periods of heavy demand or transient interruptions in the supply of hydroelectricity. In the fall and winter of its first years, when low water levels lessened that supply, Georgetown typically operated from 6 to 10 a.m. and from 3 to 8 p.m. Even when new, much of the time its boilers were banked and its turbines at rest. In 1916 only 1 percent of Stone & Webster's electricity came from steam; the total rarely exceeded 5 percent, with most of it fed into the company's streetcar system.

In 1930, much of the Georgetown plant's already marginal contribution was rendered unnecessary when Puget Sound Power & Light completed its Shuffleton steam plant in Renton. By 1948 Georgetown was operating only about 100 hours a year. In 1951 Seattle City Light purchased the plant, and it last produced electricity for use by the public in the harsh winter months of 1952-1953. A few test runs were done in later years, most recently in 1972 and 1974, but Georgetown's boilers have been cold and its turbines at rest ever since.

The Northwest's economic growth was powered largely by electricity generated by the force of moving water from the region's abundant rivers, with steam generation playing an ever-decreasing role. But steam turbines still produce most of the rest of the world's electricity, and the Georgetown Steam Plant boasts the only two surviving and theoretically operable Curtis vertical steam turbines of the more than 1,000 that were sold by General Electric in the early years of the twentieth century. The massive reinforced-concrete structure that houses them was one of the first major uses of that new material on the West Coast, designed and built by the now-fabled Frank Gilbreth. The plant was designated a National Historical Mechanical Engineering Landmark by the American Society of Mechanical Engineers in 1980 and was designated a National Historic Landmark and a Seattle Historic Landmark in 1984. A significant chapter in the history of electrical and infrastructure development in the Northwest is embodied in the Georgetown Steam Plant.