On April 1, 1946, American industrialist Henry J. Kaiser – coming off an epic run of World War II shipbuilding in Washington, Oregon, and California and looking to restructure his business interests away from wartime production – begins aluminum production operations in Mead, just north of his former hometown of Spokane. Having no experience in the metals industry, Kaiser has acquired three aluminum plants from the U.S. government earlier in the year. He opens the plants on April Fool's Day, which his peers, expecting his latest business venture to be a colossal failure, deem appropriate. The reduction facility at Mead (along with another at Tacoma, and a rolling mill at Trentwood) will soon contribute to the most profitable of all of Kaiser’s many business enterprises. Kaiser Aluminum will become the country’s third-largest producer of the versatile metal.

Good for Business, Bad for the Environment

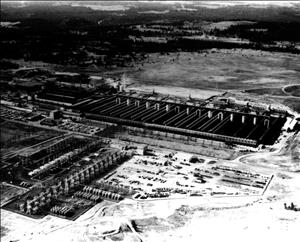

Within three months, industry publication The Iron Age reported that, "ever since the plants were leased to the Henry J. Kaiser interests, skeptics expressed doubt that they would actually be put into operation under that management. Present operations have put an end to such conjecture and interest is now centered on the question of just how large the production – and employment – will go" ("West Coast …"). At the height of its operation, the Mead smelter included 16 pot line buildings producing aluminum ingots, 27 additional support buildings, employed 2,100 people, and churned out more than 100 million pounds of aluminum in its first year of production alone.

The early successes of Kaiser Aluminum and its foundry in Mead, however, were not destined to remain. The environmental movement that began in the United States following the end of World War II quietly raised eyebrows about waste materials being generated by the production of aluminum at the smelter, and state inquiries in the late 1970s began to raise public awareness of the hazards of the facility’s industrial byproducts. According to a 1978 environmental report from the Washington State Department of Ecology, "the possibility of migrations of these pollutants into the water supplies of other users such as the Town of Mead, the State Fish Hatchery, the Golf Course and other private and public water supplies is real but undefined. It is also likely that without modification of disposal practices, concentrations of these pollutants will continue to increase with time" ("Effect Of Waste …").

Years of labor disputes in the 1990s, coupled with mounting financial difficulties and environmental concerns, ultimately led to the decision to mothball the Mead facility for good in December 2000. Kaiser Aluminum still operates the Trentwood rolling mill.

Kaiser Aluminum’s waste handling practices at the Mead site from the 1940s through the late 1970s led to cyanide and fluoride contamination in part of the Spokane-Rathdrum Prairie Aquifer and the Little Spokane River. The toxic plume averaging about a 1,000 feet wide travels in a northwesterly direction approximately 145 feet underground from the smelter site roughly 2.5 miles to the Little Spokane River, where it discharges into a series of springs that can be found along N Dartford Drive. Ecology finalized a plan in 2019 to pump out groundwater, filter and treat it, then return it to the aquifer to help clean up contamination. Additional on-site wastes were covered with asphalt to prevent rain and snow runoff from leaching back into the treated groundwater. As recently as October 2023, plans were to convert the once contaminated Kaiser property in Mead to residential properties and mixed-use development.